Matches the highest hydrocarbon cannabis processing throughputs in the industry with improved efficiency and flexibility for large-scale operations.

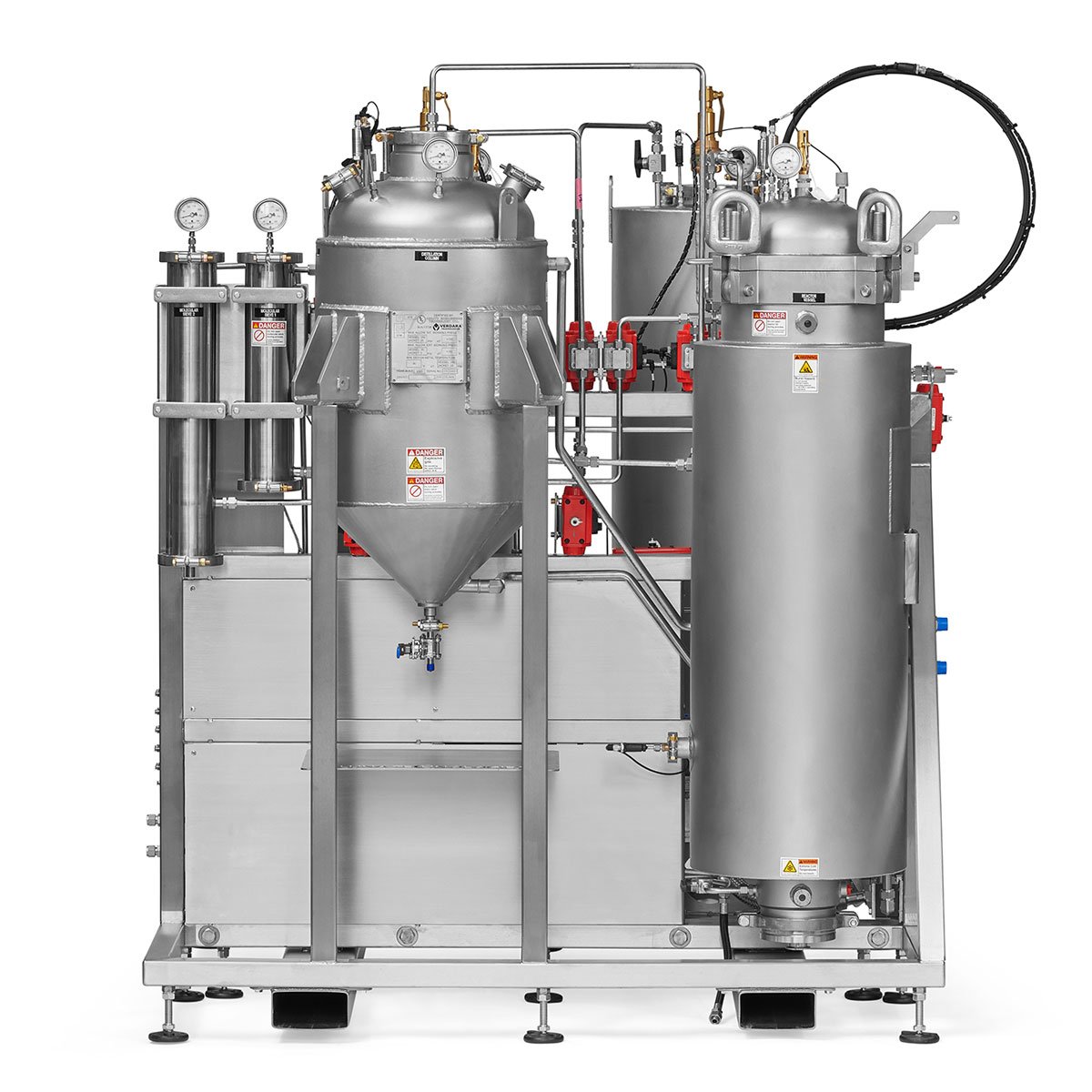

Portland, Oregon – (October 19, 2021) — Luna Technologies, a Portland-based manufacturer of hydrocarbon extraction equipment for the cannabis industry, today introduced the Oberon, a completely reimagined high-throughput hydrocarbon extractor with increased capacity to meet the needs of large-scale operators. The Oberon can process 36 pounds of fresh-frozen cannabis flower per hour, including the ability to conduct back-to-back runs with less than 60 seconds of downtime in between, matching the highest rates for a single machine in the industry. The system can also utilize an infinite number of programmable extraction recipes available through the Luna Technologies proprietary recipe book.

“The introduction of the Oberon is our response to the unprecedented demand and increasing array of subcategory preferences in cannabis concentrates and extracts,” said Jack Naito, president of Luna Technologies. “As cannabis markets mature, the sales of concentrates, including butane-based dabbable and vape products, are increasing at rates that outpace flower. As a result, manufacturers need more capacity and greater efficiency for producing the most in-demand extract products with precision.”

According to Headset, a provider of data and analytics to the cannabis industry, sales of concentrates surged more than 40 percent in 2020 within the US states of California, Colorado, Nevada, Oregon, and Washington, signaling manufacturers to ramp up production and increase investment to keep pace with shifting consumer preferences in maturing markets. Headset data also suggests concentrate and vape products are estimated to have slightly larger market shares in 2022, at the expense of flower and pre-rolls, within the USA and Canada legal markets.

Meanwhile, vape sales data compiled by Arcview Market Research and Greentake from the second quarter of 2021 saw at least double digit growth year-over-year in total sales and units sold across all of the 11 largest US States and Canadian Province markets.

Improved Capacity, Efficiency, and Production Flexibility

Luna Technologies engineers designed the Oberon from the ground up for larger producers to achieve greater energy efficiency, capacity, and flexibility within the production process. Similar to IO, Oberon utilizes hydrocarbon solvent to separate and purify cannabis oil, but with a larger extraction vessel. The higher capacity thresholds enable producers to conduct more efficient reruns and to more easily extract minor cannabinoids and terpenes, as desired.

In addition to end-to-end cannabis extraction, including accessory products for color remediation and pre-processing biomass, the Oberon provides processors with the ability to conduct back-to-back runs with less than a minute of downtime in between. Luna Technologies engineers conducted rigorous testing to create a highly efficient cooling system for the larger-capacity Oberon that maintains precise solvent temperatures through each stage of processing, further reducing downtime between runs from potentially hours to seconds while improving the overall speed, quality, and volume of production.

In total, Oberon empowers hydrocarbon processors to maximize the required utility load for lower operating costs while also cutting overhead costs relating to freezer usage, storage, and excess biomass inventory.

Luna Technologies expects to deliver its first production units of the Oberon in Q1 2022.

To see the Oberon and the entire line of Luna Technologies extraction equipment and capabilities, please visit booth #C5211 at MJBizCon, October 20-22, 2021, at the Las Vegas Convention Center in Las Vegas.